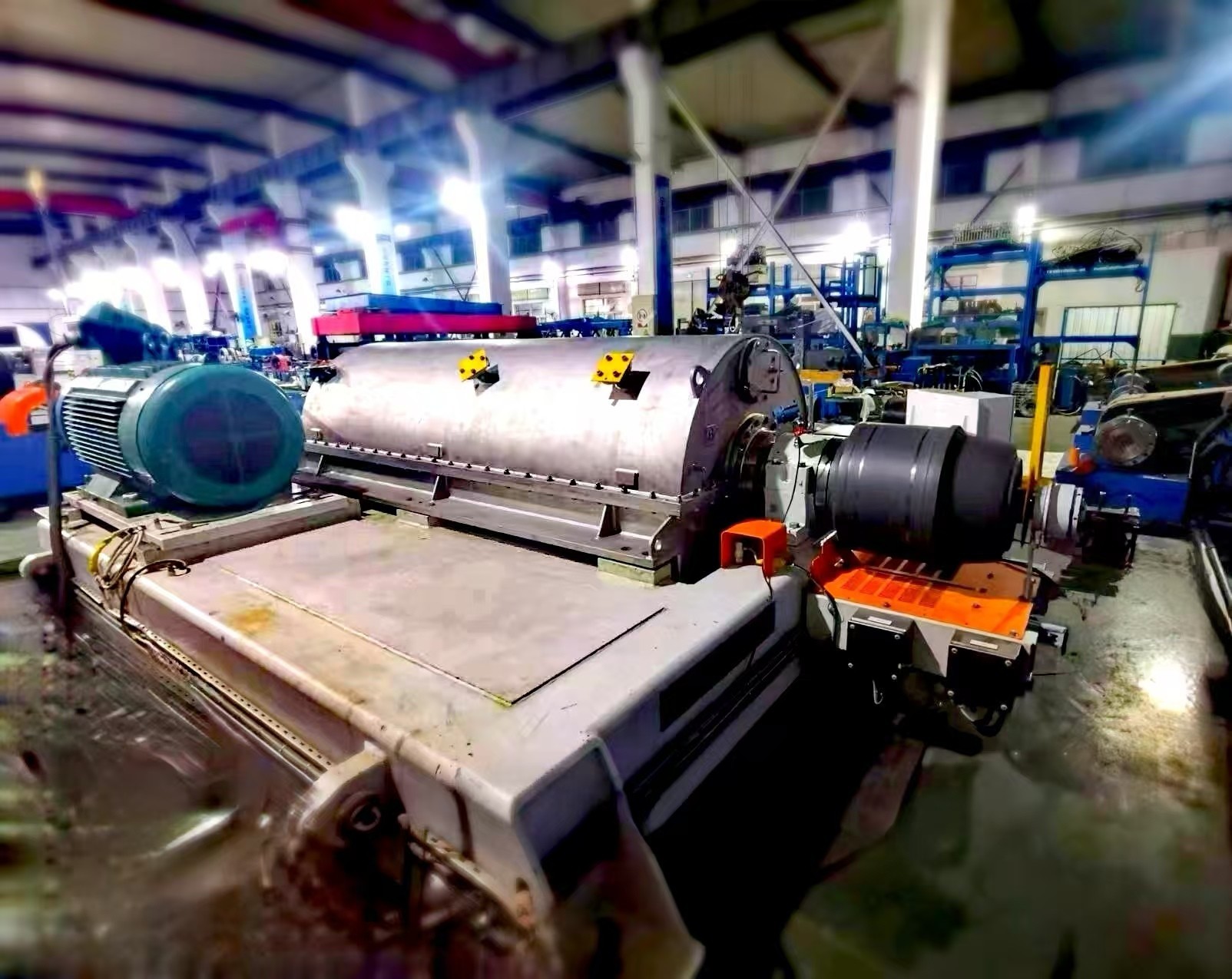

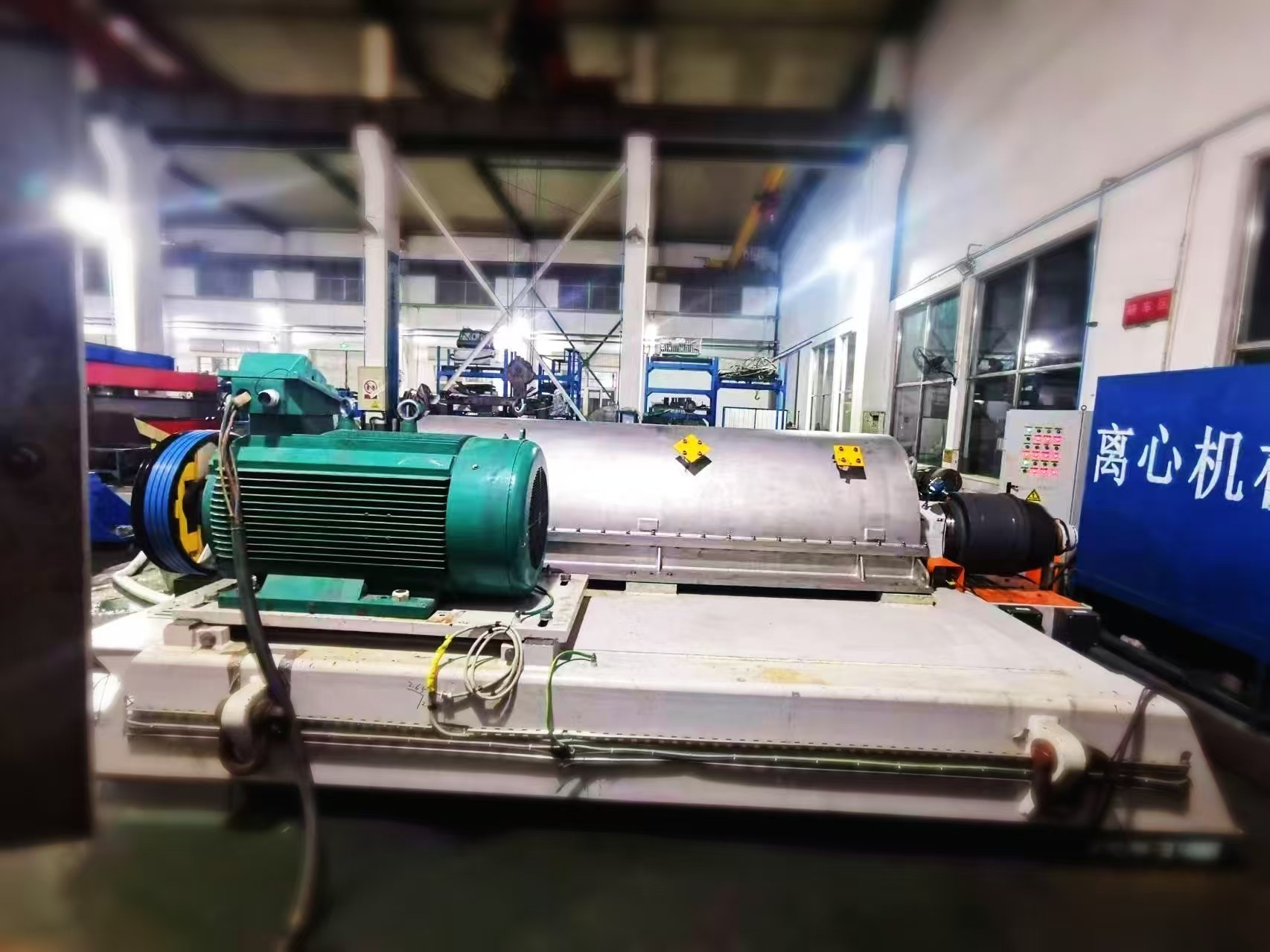

Borui Kang Company upgrades and transforms the melamine industry Brubant Large Centrifuge Equipment Successfully Delivered

Release time:

2024-12-27

Source:

On December 23, 2024, Tianjin Borui Kang Machinery Manufacturing Co., Ltd. repaired and renovated the Brubant 900 series centrifuge and differential equipment for a large chemical enterprise in Henan. All work was completed ahead of schedule, and the air and water test runs were qualified. The equipment was successfully loaded and shipped.

This upgrade and transformation of the 900 type centrifuge and differential is the first maintenance and transformation project undertaken by Borui Kang in the melamine industry for Brubant equipment (our company has localized the rotor part and centrifuge machine for Andritz equipment in this industry). The company leaders attach great importance to this and pay full attention to it throughout the process. This not only demonstrates Borui Kang's ability in large-scale equipment maintenance and renovation, but also reflects the company's further expansion in the melamine industry.

In late September 2024, our company received feedback from a customer that the Brubant centrifuge being operated on site had malfunctioned. The liquid end bearing was stuck due to lack of oil, the main shaft was violently jumping, and the bearing seat and machine seal were damaged to varying degrees. After receiving the information, our company immediately arranged for our technical personnel to go to the site to inspect the apparent phenomena and understand the specific operation of the equipment with the customer.

After the damaged equipment arrived at the Borui Kang factory, our company immediately organized production personnel to disassemble and inspect the centrifuge and differential, and arranged for design, process, technician and other personnel to conduct technical demonstration and review of the upgrade and renovation plan for the centrifuge. At the same time, in order to reach a consensus on equipment upgrade and renovation between the supply and demand sides, and comprehensively address customer demands, both parties held an online technical exchange meeting. Our company's technical personnel provided detailed explanations and clarifications on the key points, functions, and effects of the renovation plan.

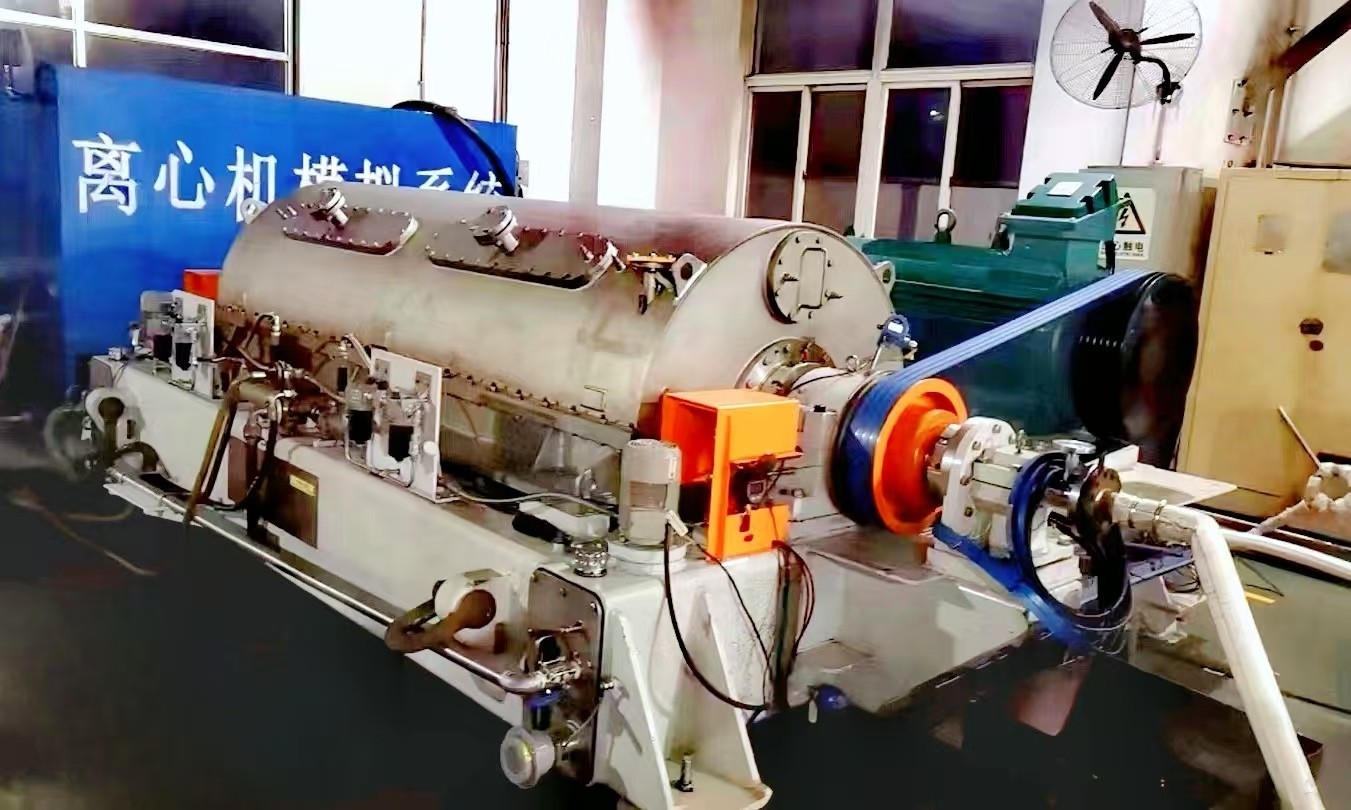

Introduction to key points of technological transformation:

1. Regarding the modification of temperature measurement points for bearing seats:

The temperature sensor configured in the original equipment is installed at the bottom of the bearing seat and measures the return oil temperature, which cannot monitor the actual temperature of the main bearing.

This renovation will open holes in the upper bearing seat and add temperature transmitters to monitor the temperature of the main bearings in real-time, ensuring the safe operation of the centrifuge.

2. Regarding the lubrication modification of bearings:

Our company has found that there are certain issues with the lubrication design of the differential side main bearing. After the oil flows in from the inlet, most of the oil flows out directly from the outlet, and a small amount splashes into the bearing, resulting in unsatisfactory lubrication effect.

So, our company has added one fuel injector on the lubrication channel to ensure that the lubricating oil is fully sprayed onto the raceway of the main bearing, improving the lubrication effect of the main bearing. At the same time, in order to monitor whether the lubrication here is normal, our company has installed a pressure transmitter at the oil inlet position for real-time monitoring to ensure the safe operation of the centrifuge.

3. Chassis modification:

The original casing contains filtrate separated from the large end, which enters the middle compartment of the casing and flows into the filter cake outlet along the bottom plate, thereby affecting the separation efficiency of the material.

Our company has analyzed the causes of this phenomenon and developed a renovation plan as follows:

a. Add a bent plate to the upper shell at the liquid phase end to collect the filtrate thrown out of the hub at the bent plate, avoiding direct landing on the hub.

b. The distance between the middle partition of the lower casing and the bottom plate is 100mm. A 60mm high water blocking plate is welded on the bottom plate to prevent the filtered liquid from accumulating here and flowing into the discharge bin.

c. Weld the pressure balance pipe mouth with a flange to allow the collected filtrate to be discharged through this pipeline.

Through transformation, the centrifuge temperature sensor can monitor the temperature of the main bearing in real time, the pressure transmitter can monitor the lubrication status of the main bearing in real time, and the filtrate inside the casing can be effectively collected, thereby ensuring the separation effect of centrifuge materials and the safe operation of centrifuge equipment.

The smooth progress of this maintenance and renovation work is an important demonstration of Borui Kang's technical strength and market competitiveness, and has significant implications for the company's impact in the melamine industry. Under the supervision and guidance of Mr. Su and Mr. Wu, and with the joint efforts of employees from various departments such as technology and production, the company strictly follows the process flow from contract signing, equipment entry, determination of maintenance and renovation plans, process inspection and control, trial operation and other aspects. Each process is controlled by professional personnel, and every detail is guaranteed to be flawless. All requirements and efforts are made to not disappoint the trust of customers.

Borui Kang personnel ensured the smooth delivery of the equipment with their professional strength and practical actions, and completed the delivery several days ahead of the contract expectations. Efforts should be made to prioritize customer requirements and industry standards, ensuring quality while pursuing timeliness.

The truck delivered with full load not only delivers qualified products, but also carries the sincerity of Borui Kang people towards customers, their responsibility and quality assurance for equipment products. We promise to continue to serve and assist customers with a high sense of responsibility and full enthusiasm for work, leap forward, and reach new heights!

Related News