The localization transformation of the German SIDELI TSDT1100 centrifuge is running stably Brekon 2024 won another new order

Release time:

2024-06-28

Source:

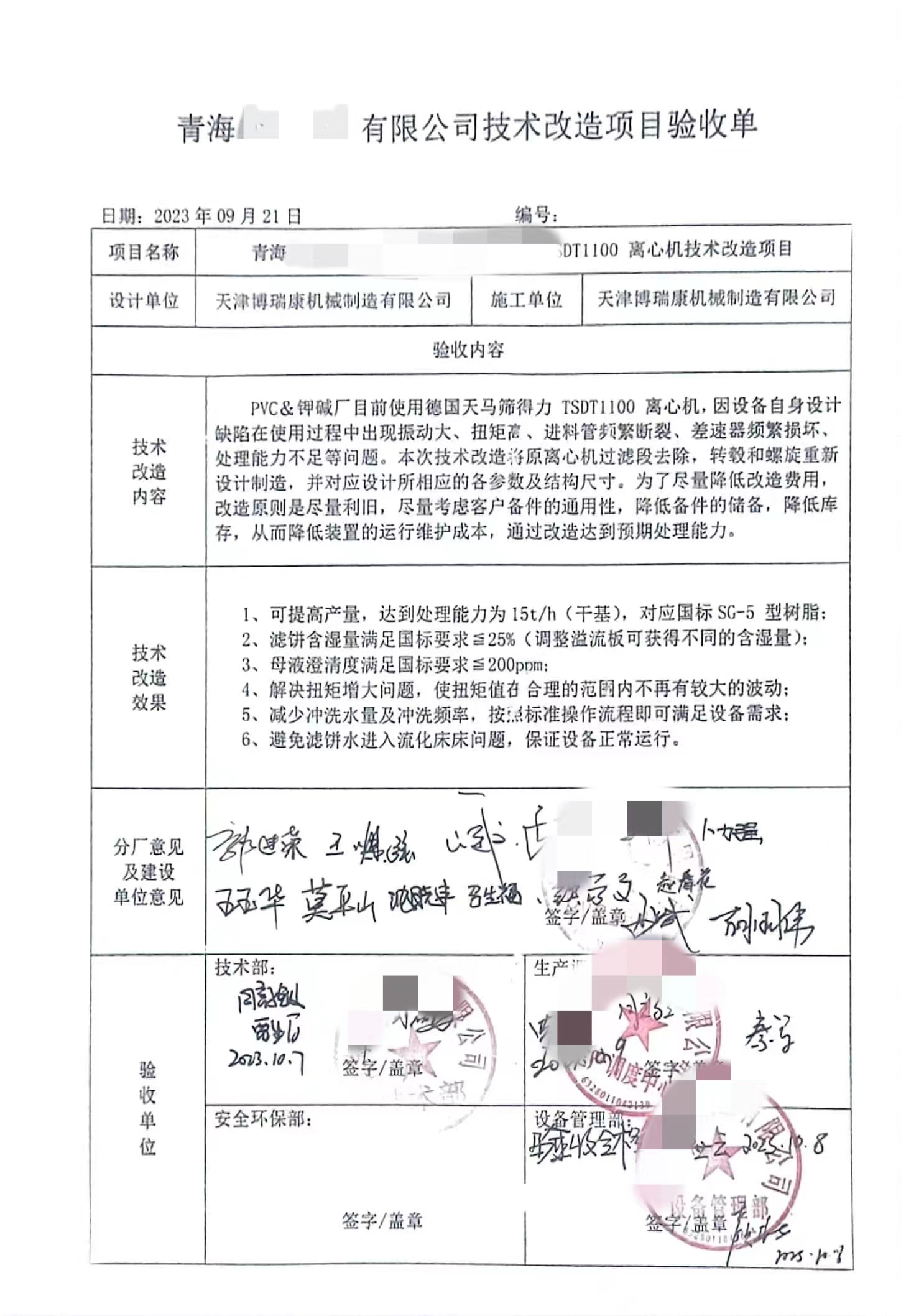

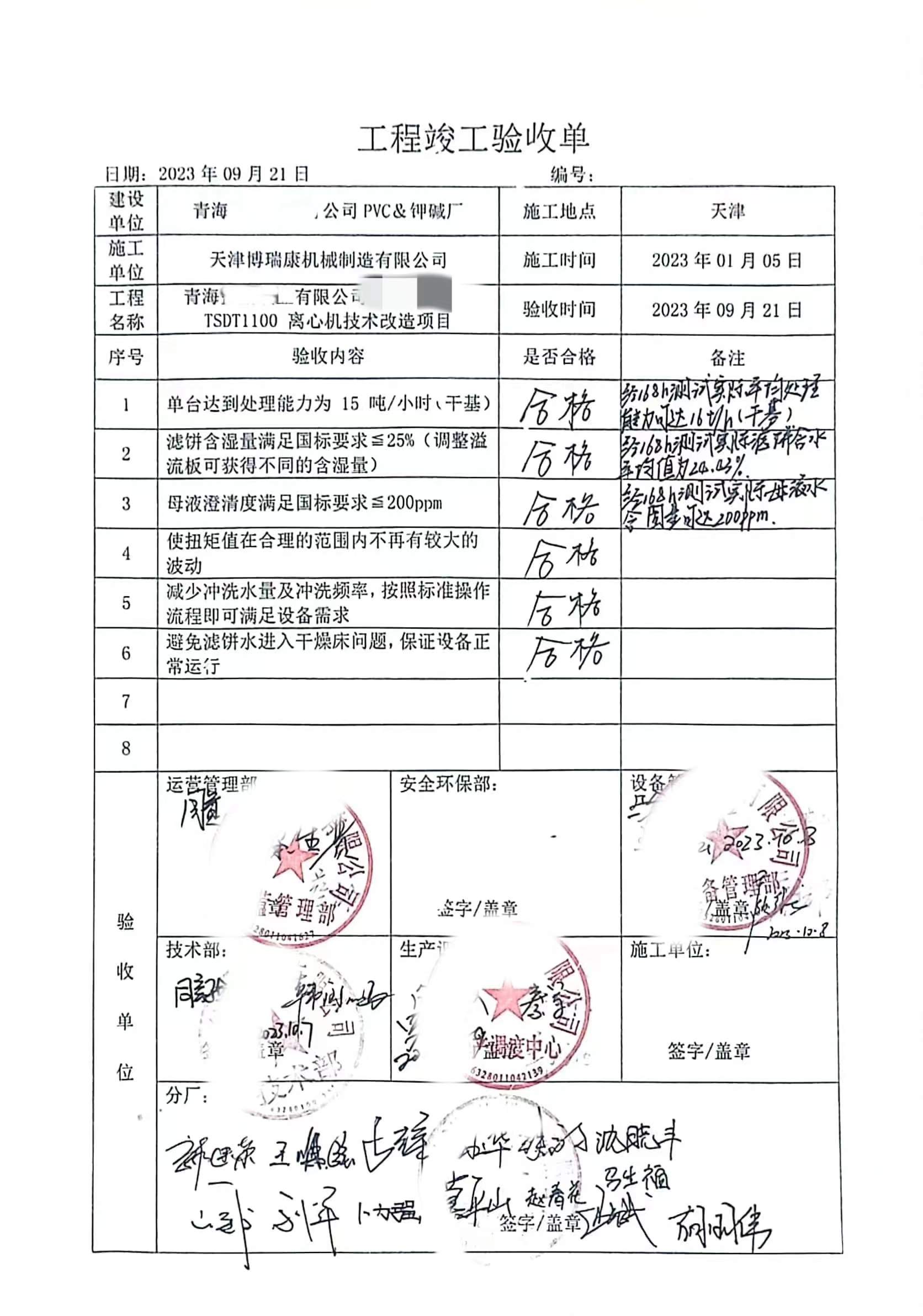

SIDELI is a traditional and old centrifugal equipment manufacturer abroad, and it is also one of the imported brands currently used online in China's chemical industry. In April 2019, Tianjin Boruikang Machinery Manufacturing Co., Ltd. went to a large enterprise in Qinghai for technical exchanges, and the equipment used by the enterprise was the German Sieddeli TSDT1100 centrifuge. Brecom actively provides technical support and solutions, and the two sides have a preliminary understanding.

The trust between the two sides comes step by step! In August 2021, Boruikang reached the first cooperation with a large enterprise in Qinghai, and the differential for the centrifuge of this model was suddenly damaged, and the damage was almost scrapped. The connection between the differential and the host of this model is inline, so the accuracy of the host, including any abnormal conditions such as material blocking, will directly act on the differential, which has a great impact on the normal operation of the differential. In view of the problems in operation, Boruikang has carried out a number of design improvements such as lubrication methods for the differential, so that the differential can be successfully transformed at one time. Later, three differential models of the Siebrix TSDT1100 model were overhauled for the customer, and the technical ability and professionalism of Boykon left a deep impression on the company.

The differential is tested on the test bench

Based on the three successful cooperation between the two parties in the early stage, after systematic research and repeated demonstrations in July 2022, Boruikang signed a contract with the company for the transformation of a Siebtechnik TSDT1100 centrifuge. The main problems with Siebtechnik TSDT1100 centrifuges are:

1. The production capacity is not up to standard, the design capacity is 18 tons/hour, and the actual output is about 10 tons/hour;

2. Frequent flushing, serious material blockage, once the load is increased, the torque increases sharply, and the equipment cannot be operated;

3. The filter cake water enters the drying bed, which affects the stable operation of downstream equipment;

4. Frequent breakage of the feed pipe;

5. The separated PVC powder is doped with black, red and yellow powder spots, and the quality of the finished product decreases.

1. Cause analysis

The Brekon Technology Center has conducted a comprehensive analysis of the causes of the above failures, and our company believes that:

1. The output end of this model of centrifuge is provided with a filter screen, due to the characteristics of PVC powder, part of the powder will be bonded to the screen wall in the output process, and the materials accumulated in the filter screen can not be discharged smoothly, and with the continuous production or the increase of output will cause the increase of torque, resulting in the destruction of dynamic balance, resulting in excessive vibration of the equipment and unable to operate normally, which is the key reason why the production capacity can not be improved.

2. Regarding the problem of black, red and yellow powder dots doping in the separated PVC powder, this is also caused by the structure of this centrifuge, because the equipment outputs the dried filter cake to the filter section, and further dehydrates and dries, so that the material passes through two drying zones and the residence time is too long, resulting in the change of the properties of some materials and reducing the quality of the finished product.

3. In order to solve the problem of material accumulation without clogging the screen, the customer rinses once a day 24 hours a day, washes once every 8 hours, and washes the screen with a small flow of water from time to time, which causes the filter cake water to enter the drying bed with the material, affecting the stable operation of downstream equipment.

Second, the transformation plan

After repeated demonstrations and bold innovations, Boyicon Technology Center has made a large-scale structural transformation, and the main contents of the transformation are as follows:

1. Redesign and replace the hub cone section, and remove the filter screen part;

2. Redesign and replace the spiral, and optimize the design of the structure of the spiral hub core and the various parameters of the spiral to ensure the gap between the spiral and the rotating hub, so as to solve the problem that the production capacity is not up to standard;

3. The material guide strip of the rotor hub is removed and replaced with the structure of the guide trough to optimize the force in the separation process of the centrifuge, so that the material can be pushed out more smoothly, which is more conducive to ensuring the mechanical properties of the centrifuge and making the long-term operation of the equipment more stable;

4. Re-design the feed pipe to solve the problem of frequent damage to the feed pipe caused by the tremor caused by the material with a certain pressure spraying out of the feed pipe due to the long feed pipe;

5. The principle of transformation is to make use of the old as much as possible, and try to consider the versatility of spare parts, so as to reduce the inventory of spare parts, reduce the cost of transformation and future maintenance.

Through the design and improvement of the original structure of the centrifuge, Boyicon not only meets the requirements of the three major technical indicators of the centrifuge, but also increases the production capacity from 10 tons/hour to 16 tons/hour, passes the customer's 168-hour operation test at one time, and successfully obtains the completion acceptance report!

After-sales service personnel are trained and explained at the customer's site

After-sales service personnel are trained and explained at the customer's site

In March 2024, after seven months of stable online operation of the transformation equipment, also in the context of the economic downturn and the substantial reduction of production investment, the company once again reached a cooperation with Boruikang, and Boruikang won another 2 new orders for transformation! At present, 2 sets of equipment have successfully arrived at the factory and are in full swing for transformation and maintenance.

The equipment to be transformed arrives at the factory and is ready to be unloaded

The pivot and spiral of the centrifuge are the two most important core components, and Bricon has completely designed the spiral assembly and the hub cone. These cases fully illustrate that Boruikang can not only implement localized replacement or maintenance of original imported parts, so that the equipment can meet the same use requirements as the original machine; Moreover, for the original design of the imported centrifuge is unreasonable or the selection error of the target separator, Boycom has the ability to carry out applicability technical transformation, improve the performance of the centrifuge through structural improvement, increase production capacity and comprehensively solve the customer's problems in actual use.

On the one hand, it shows that our core technical strength can be comparable to imported equipment, and on the other hand, it once again confirms that the bold and innovative secondary technology transformation products of Boruikang not only stay at the level of excellent design, but also the product quality can stand the test of time and withstand the production of continuous and stable operation. Practice is the only criterion to test the truth, Boruikang products have been repeatedly tested by the market, has been recognized and trusted by the majority of customers, Boruikang will continue to adhere to our continuous improvement of this work policy, for customers for the chemical industry to continue to contribute our strength.

The road is simple, hard work is essential, do not abandon the micro, do not give up an inch!

Related News